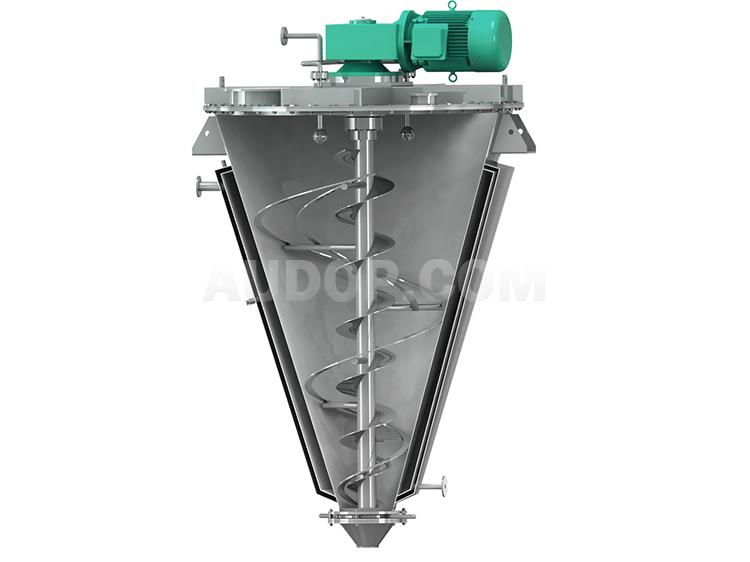

Single-Screw Cone Mixer

- No Mixing Dead Ends: Combined with the design of conical barrel wall and ribbon scraper, it effectively eliminates material residue dead ends and improves mixing uniformity of the single-screw cone mixer.

- Strong Adaptability: The ribbon scraper can efficiently handle materials with poor fluidity or certain viscosity, reducing material wall adhesion.

- Flexible Operation: The central screw supports forward or reverse design, and the mixing method can be adjusted according to material characteristics.

- Stable Operation: Driven by a cycloidal pinwheel reducer, it ensures stable operation of the equipment, reducing noise and energy consumption.

- Wide Application Range: Compatible with the mixing needs of materials in various forms such as powder and liquid, meeting the production requirements of multiple scenarios.

Overview

The single-screw cone mixer is an industrial mixing equipment designed for powder, granular and solid-liquid materials, and is widely used in material processing scenarios across multiple industries. With scientific structural design and precise motion control, this single-screw cone mixer achieves uniform mixing of powder-powder, liquid-liquid and powder-liquid materials. It meets the requirements for material mixing precision and efficiency in different production processes, and is an important equipment in the material mixing link of industrial production.

The single-screw cone mixer is an industrial mixing equipment designed for powder, granular and solid-liquid materials. It adopts a conical cylinder and single-screw structure design to ensure no residual material discharge, and is widely used to meet the uniform mixing needs in chemical, pharmaceutical, food additive and other fields. After materials enter the cylinder through the top feeding port, the screw shaft forms three mixing effects of convection, shear and diffusion under the combined motion of revolution and rotation. The materials are lifted to the top along the cone wall and then fall naturally, realizing uniform circumferential and axial distribution.

Main Structure:

- Screw System: The single-screw shaft drives material circulation through the combined motion of rotation and revolution.

- Transmission Device: The motions of the rotation motor and revolution motor are adjusted to a reasonable speed through worm gears and gears, and then transmitted to the screw to realize both rotation and revolution motions.

- Cylinder Cover Part: The cylinder cover supports the entire transmission part, which is fixed on the cylinder cover with screws. The cylinder cover is equipped with a feeding port, an observation port, a cleaning port and a maintenance hole.

- Cylinder Body Part: The cylinder body has a conical structure and is used for holding materials, enabling rapid and clean discharge without material accumulation and no discharge dead ends.

- Discharge Valve: The discharge valve is installed at the bottom of the cylinder body for controlling materials and discharging. It has three structural forms: manual, pneumatic and electric. A liquid discharge valve (slurry valve) can be added according to user needs.

- Liquid Spraying System (Optional): Supports solid-liquid mixing process with evenly distributed nozzles.

Working Principle:

The single-screw cone mixer is connected with a cycloidal reducer to the central screw and the outer ribbon, which operate at the same speed. During operation, the central screw lifts the mixed materials from the bottom to the top. At the same time, the outer ribbon with a higher linear speed lifts the materials upward along the conical barrel wall. Under the action of centrifugal force, these two motions throw the materials into the space along the tangential direction. The materials undergo intense convection, shear and diffusion, so as to achieve the purpose of rapid mixing (the central screw can also be made into a reverse screw).

Application Scope:

The single-screw cone mixer is widely used in chemical, metallurgy, food, pharmaceutical, chemical fertilizer, coating, pigment, dye, pesticide, rubber feed, additive, refractory material, fine chemical, new material, electronic plastic, ceramic, mining, building material and other industries. This single-screw cone mixer has a wide adaptability to mixed materials. It can mix and stir powder, granular materials, slurry or viscous materials, and can be equipped with a liquid spraying system. It can be designed into process conditions such as vacuum state, pressure state, heating or cooling according to user requirements, to meet the mixing and stirring of materials under different process conditions. It will not cause overheating to heat-sensitive materials, will not crush or grind granular materials, will not cause stratification and segregation when mixing materials with very different specific gravity and particle sizes, and has good adaptability to the mixing of coarse, fine and ultra-fine particles, fibers or flakes.

Maintenance:

- Regular Inspection: Before operation, check whether the connection of the drive system is firm and whether the screw and ribbon are loose or deformed;

- Cleaning and Maintenance: Timely clean the residual materials in the barrel after each use to avoid material accumulation and caking affecting the next mixing effect of the single-screw cone mixer;

- Lubrication Maintenance: Regularly add suitable lubricants to the reducer and rotating parts to ensure smooth operation;

- Load Control: Avoid overloading the equipment due to excessive feeding to extend the service life of the equipment;

- Abnormal Handling: If abnormal conditions such as abnormal noise and vibration occur during operation, stop the machine immediately for inspection, and continue to use it only after troubleshooting.

Technical Parameters

Technical Parameters

| Model | Volume(m³) | Loading Factor | Yield(KG) | Speed((rpm) | Power(KW) |

| DZDH-0.1 | 0.1 | 0.6 | 60 | 58 | 1.1-2.2 |

| DZDH-0.5 | 0.5 | 0.6 | 300 | 48 | 3-5.5 |

| DZDH-1 | 1 | 0.6 | 600 | 40 | 4-7.5 |

| DZDSH-2 | 2 | 0.6 | 1200 | 34 | 5.5-11 |

| DZDH-3 | 3 | 0.6 | 1800 | 30 | 7.5-15 |

| DZDH-4 | 4 | 0.6 | 2400 | 28 | 11-18.5 |

| DZDH-5 | 5 | 0.6 | 3000 | 25 | 15-22 |

| DZDH-6 | 6 | 0.6 | 3600 | 22 | 18.5-30 |

| DZDH-8 | 8 | 0.6 | 4800 | 20 | 22-37 |

| DZDH-10 | 10 | 0.6 | 6000 | 18 | 30-45 |

| DZDSH-15 | 15 | 0.6 | 9000 | 16 | 45-75 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Reaction Kettle

- Strong sealing & precise temperature control: Supports heating and cooling, and can stably maintain the temperature range required for reactions.

- Efficient stirring: Equipped with professional stirring devices to ensure uniform material mixing and sufficient reaction.

- Suitable material selection: Common stainless steel material, acid and alkali corrosion resistance, suitable for different reaction systems.

- Safe and reliable: Equipped with multiple pressure and temperature monitoring devices and explosion-proof devices to reduce reaction risks.

- Flexible specifications: Volumes range from milliliter level to cubic meter level, which can meet the needs from laboratory small-scale tests to industrial mass production

PVC High Speed Mixer

- All important parts (bowl, mixing tool, electrical control) are manufactured in AUDOP Company, which ensure the quality of machine.

- All material in contact with product is SS304 or aluminum alloy and the product will not be contaminated.

- Short mixing time, easy and convenient to clean high output.

- Mixing tool coated with wear-resistant material, which can increase service life and past dynamic and balance test,running smoothly.

- Mature product technology based on mixing blade with high tip speed (up to 40m/sec).

- High throughput rate at low, specific energy consumption.

- Rapid, perfect after-sales service.

High speed Hot and Cooling Mixer Machine

Highlighted Features:

1. Material: All contact parts are made of S.S.304 stainless steel.

2. Treatment: Inner wall is highly polished, with layers for heat preservation.

3. Shaft Seal: metal labyrinthy seal + air-purge seal +oil seal, triple seal to guarantee no leak of material.

4. Temperature control: With control system to monitor material temperature in real time.

Two thermal resitstors, one is for controlling temperature, the other one is for overheat alarm.

5. Driving Motor: With Frenquency convetor to realise speed adjustment of main shaft.

6. Cover-opening: With pneumatic system as well as hand wheel to guarantee the cover can be opened even no air and electricity.Horizontal Mixer

- High Mixing Efficiency: The specially designed mixing device and rotation method of the horizontal mixer make materials form multiple vortices in the barrel, greatly accelerating the mixing speed.

- High Mixing Uniformity: Even if there are differences in specific gravity and particle size of materials, the staggered mixing blades of the horizontal mixer tumble and sprinkle quickly and violently, which can still achieve excellent mixing effect.

- Wide Application Range: The horizontal mixer is suitable for mixing a variety of materials, such as powders, semi-fluids, etc.

- Easy Operation: The horizontal mixer has a compact structure, simple operation, and easy daily maintenance and upkeep.